Leave Your Message

When it comes to maintaining your bicycle, selecting the right interior tube is crucial for ensuring a smooth and safe ride. An interior tube serves as the essential component that holds the air within the tire, effectively influencing the overall performance, comfort, and durability of your bike. With a plethora of choices available on the market, it can be overwhelming to determine which interior tube best suits your specific needs and riding conditions.

In this comprehensive guide, we will explore key factors to consider when choosing an interior tube, such as size compatibility, material options, and valve types. Understanding these elements will not only enhance your biking experience but also provide peace of mind knowing that you have made an informed decision. Whether you are a casual rider or a seasoned cyclist, knowing how to select the right interior tube is an essential skill that can dramatically impact your bicycle's efficiency and reliability. Join us as we delve into the top tips and insights for selecting the perfect interior tube for your unique cycling adventures.

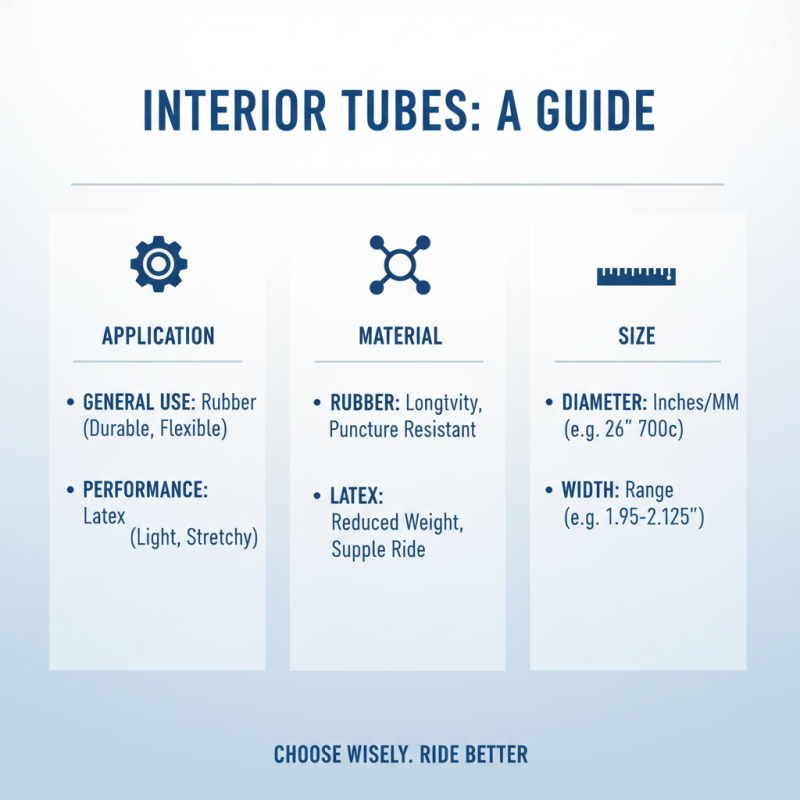

When selecting an interior tube, understanding the various types available is essential for ensuring you meet your specific needs. Interior tubes are commonly categorized based on their application, material composition, and size. For instance, rubber tubes are widely used due to their durability and flexibility, making them ideal for general applications. In contrast, latex tubes are lighter and often preferred for their stretchability, although they may not withstand as much wear and tear.

Another important classification is based on the intended use of the tube. For example, tubes designed for high-pressure applications require a thicker wall to handle the stress without bursting. Conversely, tubes intended for low-pressure situations can be thinner and lighter. It is crucial to consider the environment in which the tube will be used as well; some materials are better suited for specific conditions, such as exposure to chemicals or extreme temperatures.

Lastly, size plays a significant role in determining the right interior tube. Measurements should account for both the diameter and length needed for effective performance. A tube that is too small will not fit properly, while one that is too large may lead to inefficiencies in operation. Therefore, evaluating these factors thoroughly will help ensure you choose the right interior tube that best fits your requirements.

When selecting an interior tube for your project, one of the foremost factors to consider is the material of the tube itself. Different materials offer varying degrees of flexibility, durability, and resistance to environmental factors. For instance, tubes made of synthetic materials might provide enhanced resistance to moisture and chemicals, making them suitable for specific applications where exposure to harsh conditions is a concern. Conversely, natural rubber tubes can offer superior elasticity and shock absorption, ideal for projects requiring high flexibility and impact resistance.

Another critical factor is the size and diameter of the tube you need. It's essential to ensure that the dimensions align with your project requirements to prevent misfits that could lead to inefficiencies. Additionally, consider the weight capacity and load distribution characteristics of the tube. Different applications may require specific weight ratings, so understanding the demands of your project is crucial in determining the appropriate tube specifications. Lastly, take into account the intended use of the tube—whether it’s for pneumatic applications, hydrostatic needs, or for structural purposes—as this will dictate the structural integrity and performance requirements necessary for your interior tube choice.

| Factor | Description | Consideration |

|---|---|---|

| Size | Choose the correct diameter and length for your project | Ensure compatibility with your existing equipment |

| Material | Select materials that fit the fluid type and temperature | Determine if you need abrasion resistance or chemical resistance |

| Pressure Rating | Match the tube's pressure rating with your system's requirements | Consider maximum pressure and safety margins |

| Temperature Range | Ensure the tube can handle the temperatures of the fluids | Consider both low and high-temperature extremes |

| Flexibility | Assess if you need a flexible or rigid tube based on application | Evaluate routing and installation constraints |

When selecting the right interior tube for your equipment, it's essential to evaluate its compatibility with your specific needs. Different applications demand various tube specifications, such as size, material, and intended use. For instance, if you are utilizing the tube in a high-pressure environment, you'll want to opt for a tube that can withstand such conditions to ensure optimal performance and safety. Identifying the exact requirements of your equipment will help you narrow down your options, making it easier to choose a tube that enhances the durability and efficiency of your setup.

Furthermore, it's critical to consider the operational context in which the tube will be used. Will it be subject to extreme temperatures, moisture, or specific chemical exposures? Each factor can influence the longevity and functionality of the tube, so matching the material properties of the tube to your environment is key. For example, a tube that performs well in dry conditions may not be suitable for damp areas, leading to premature failure. By taking into account factors like temperature tolerance and environmental exposure, you can ensure that the tube you choose effectively meets the demands of your operations.

When it comes to choosing the right interior tube, assessing material durability and performance is crucial for ensuring longevity. A recent industry report from the International Journal of Materials Science highlighted that the choice of materials significantly impacts the lifespan and functionality of interior tubes. For example,

high-density polyethylene (HDPE) is often favored for its resistance to wear and tear, with a typical lifespan of 50 years in non-submerged conditions, compared to lower-grade materials, which may only last a fraction of that time.

Additionally, performance under various environmental conditions must be evaluated. Research indicates that tubes made from thermoplastic elastomers (TPE) exhibit superior flexibility while maintaining structural integrity in fluctuating temperatures. According to the American Society for Testing and Materials (ASTM), TPEs can withstand extreme temperatures ranging from -40°F to 212°F without compromising their performance. This allows for versatility across different applications, from residential to industrial needs. Ultimately, selecting the right material based on these durability and performance metrics can lead to significant cost savings and reduced maintenance over the years.

When selecting the right interior tube for your needs, budgeting plays a crucial role in the decision-making process. According to a report by the National Association of Home Builders, nearly 30% of homeowners identify budget constraints as a primary challenge when undertaking renovation projects. This indicates that understanding cost considerations can significantly impact your choices. For instance, the average price range for interior tubes varies widely based on materials and specifications, with standard tubes costing between $15 to $40. However, premium options can exceed $100, highlighting the importance of establishing a budget based on your specific requirements.

In addition to the initial purchase price, it's essential to factor in installation costs and potential future maintenance. Research from the Home Improvement Research Institute shows that homeowners often overlook the labor costs, which can add another 20-30% to the overall expense of installing interior tubes. Furthermore, selecting a tube with a longer life expectancy can lead to savings in the long term, as it may mean fewer replacements and repairs. Therefore, a thorough understanding of the total cost of ownership—initial purchase, installation, and maintenance—will help ensure that your investment aligns with your budget while meeting your functional needs.