Leave Your Message

In today's fast-paced world, optimizing energy efficiency is more crucial than ever, especially in HVAC (Heating, Ventilation, and Air Conditioning) systems. An air chamber plays a pivotal role in maintaining optimal airflow and air quality, significantly impacting energy consumption and operational costs. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), optimizing HVAC systems can lead to energy savings of up to 30%. By fine-tuning the design and functionality of the air chamber, building owners can reduce energy waste and create a more sustainable environment. This not only benefits individual facilities but also contributes to broader environmental goals. Therefore, understanding and implementing effective strategies for air chamber optimization is essential for achieving maximum efficiency in HVAC systems, leading to cost savings and improved air quality for occupants.

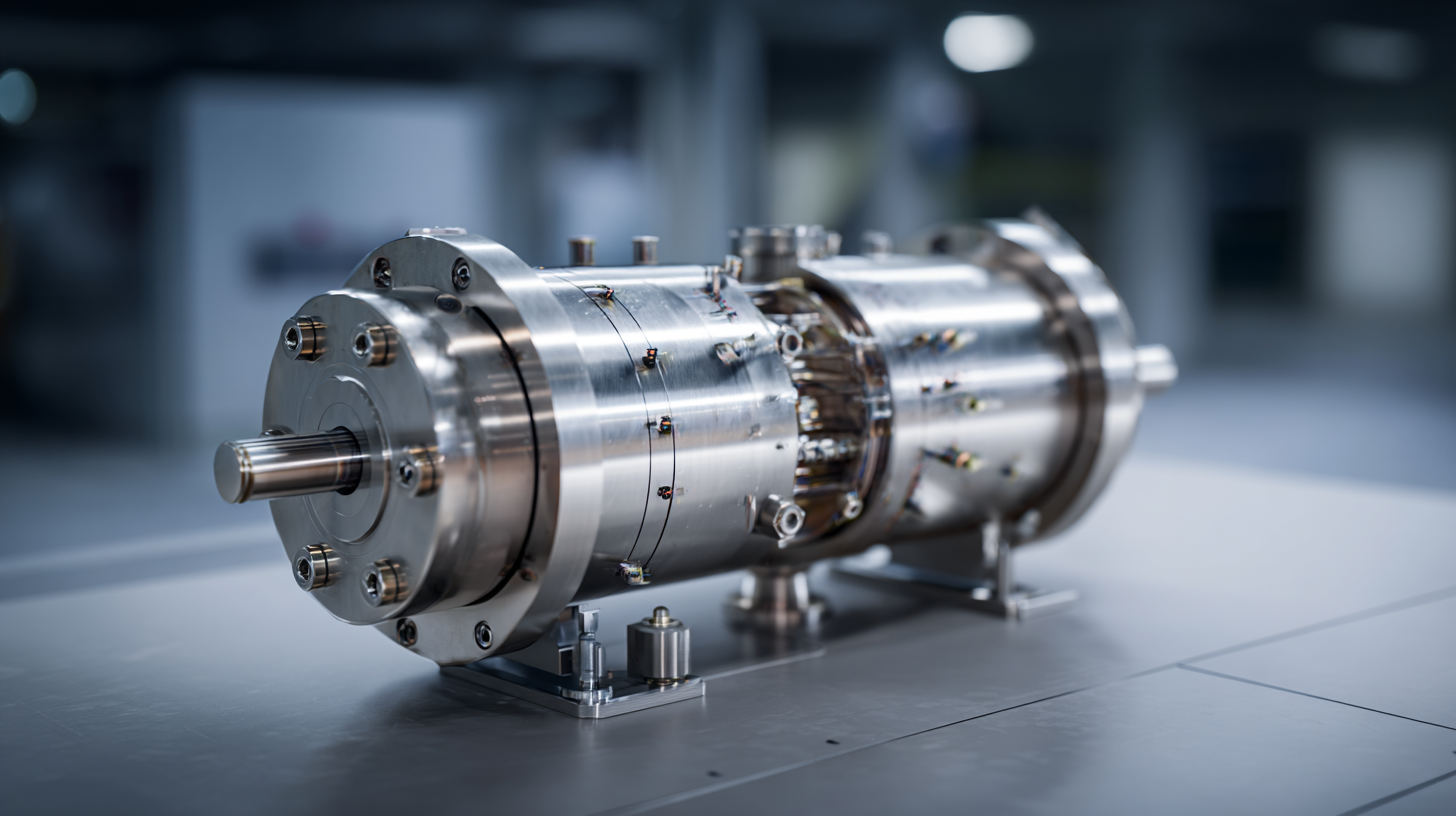

Air chambers play a crucial role in various applications, particularly in enhancing the efficiency of hydraulic systems and optimizing energy use in plumbing systems. Understanding the basic principles of how air chambers function can significantly impact overall performance. An air chamber is essentially a vessel filled with air that compresses when water flows through it. This compression helps absorb shock waves caused by changes in water flow, preventing pipe damage and reducing noise. The air cushion also aids in maintaining a steady flow of water, minimizing pressure fluctuations that can lead to inefficiencies.

To maximize the efficiency of your air chamber, it is vital to consider its design and placement. The size of the chamber should be appropriate for the volume of water it is servicing, ensuring sufficient air cushion without excessive pressure. Additionally, regular maintenance, such as checking for leaks or ensuring the chamber is free from water accumulation, is necessary to maintain optimal performance. By paying close attention to these factors, the air chamber can serve its intended purpose effectively, contributing to a more efficient system overall.

When optimizing your air chamber for maximal efficiency, it is crucial to first identify common issues that can adversely affect its performance. One of the primary problems is air leaks, which can stem from faulty seals or connections. These leaks not only diminish the air chamber's pressure but also lead to increased energy consumption as the system works harder to maintain the desired level of pressure. Regularly inspecting for leaks and ensuring that all fittings and seals are in good condition is essential for maintaining optimal performance.

Another prevalent issue is the accumulation of moisture within the air chamber. Excess moisture can lead to corrosion and reduced functionality, jeopardizing the overall system efficiency. Implementing a moisture separation system can help minimize this risk and improve air quality within the chamber. Additionally, monitoring the ambient temperature is important, as temperature fluctuations can influence the air density and, consequently, the system's efficiency. By addressing these common issues, you can significantly enhance the performance and longevity of your air chamber.

| Issue | Symptoms | Potential Causes | Solutions | Efficiency Impact (%) |

|---|---|---|---|---|

| Air Leakage | Inconsistent performance | Worn seals, damaged pipes | Inspect and replace seals, repair pipes | 30% |

| Insufficient Air Pressure | Poor device operation | Compressor failure, clogged filters | Regular maintenance, replace filters | 25% |

| Dirty Components | Reduced airflow | Dust, debris accumulation | Regular cleaning schedule | 20% |

| Temperature Fluctuations | Variable efficiency | Improper insulation, environmental factors | Upgrade insulation, control environment | 15% |

| Old Equipment | Frequent breakdowns | Aging machinery | Consider upgrading to new models | 40% |

Maintaining and cleaning your air chamber is essential for ensuring optimal performance and longevity. Regular upkeep not only enhances efficiency but also prevents operational problems down the line. Start by inspecting your air chamber for any signs of wear or damage. This proactive approach can help you identify issues before they escalate. Additionally, consider using a soft brush or cloth to wipe down the exterior and remove dust build-up that could impact airflow.

Tips: Clean the filters frequently, as clogged filters can significantly reduce airflow and increase energy consumption. Replacing them on a regular schedule will help maintain a steady and efficient air supply. Also, remember to check and clear any debris from the inlet and outlet ducts to promote consistent performance.

Furthermore, descaling the internal parts of your air chamber can improve efficiency. Over time, mineral deposits can accumulate and hinder operation. Using a gentle, non-corrosive cleaning solution to descale can help sustain peak performance. Make this a part of your routine maintenance, and you’ll not only optimize the air chamber’s efficiency but also prolong its useful life.

Adjusting air pressure settings in your air chamber is crucial for enhancing overall efficiency.

A report from the International Air Compressor Association indicates that optimizing air pressure can increase energy efficiency by up to 30%. This is especially significant in industrial applications where compressed air often represents one of the largest energy costs. By fine-tuning your pressure settings to match the exact requirements of your system, you reduce unnecessary energy consumption and improve the lifespan of your equipment.

Moreover, maintaining the correct air pressure helps in achieving consistent product quality.

A study conducted by the Compressed Air and Gas Institute found that for every 2 psi increase in air pressure, energy usage can increase by about 1%. This means that not only can excessive pressure lead to higher energy bills, but it can also cause wear and tear on machinery and increase maintenance costs.

Regularly monitoring and adjusting air pressure not only safeguards equipment but also ensures optimal performance, leading to better productivity outputs.

Upgrading components in your air chamber is essential for maximizing its efficiency and performance. Start by evaluating the current equipment you have in place. Look for advanced components that offer improved energy efficiency, such as high-performance compressor systems and optimized air distribution systems. These upgrades can significantly enhance the chamber's ability to maintain consistent pressure and temperature, which is crucial for achieving desired results in various applications.

When selecting the right equipment, consider compatibility and long-term reliability. Ensure that new components seamlessly integrate with existing systems to avoid operational disruptions. Additionally, prioritize vendors known for quality and customer support, as this can make a significant difference in the longevity and efficiency of your air chamber. Investing time in researching options—such as variable frequency drives for compressors or advanced control systems—can lead to substantial operational improvements and cost savings over time.