Leave Your Message

Butyl Rubber is a crucial material in various industries, known for its exceptional properties. Dr. John Smith, a leading expert in synthetic rubbers, once remarked, "Butyl rubber is an unsung hero in industrial applications." This statement highlights the importance of Butyl Rubber yet often overlooked.

This unique rubber is resistant to gas and offers excellent aging stability. It plays a key role in manufacturing tires, adhesives, and sealants. The versatility of Butyl Rubber makes it essential for improving product performance. Each application benefits from its ability to maintain integrity under pressure and temperature fluctuations.

Despite its advantages, the industry faces challenges. Sourcing high-quality raw materials can be difficult. Furthermore, environmental concerns regarding production processes call for innovation. These aspects remind us that while Butyl Rubber is vital, continuous improvement and reflection are necessary for a sustainable future.

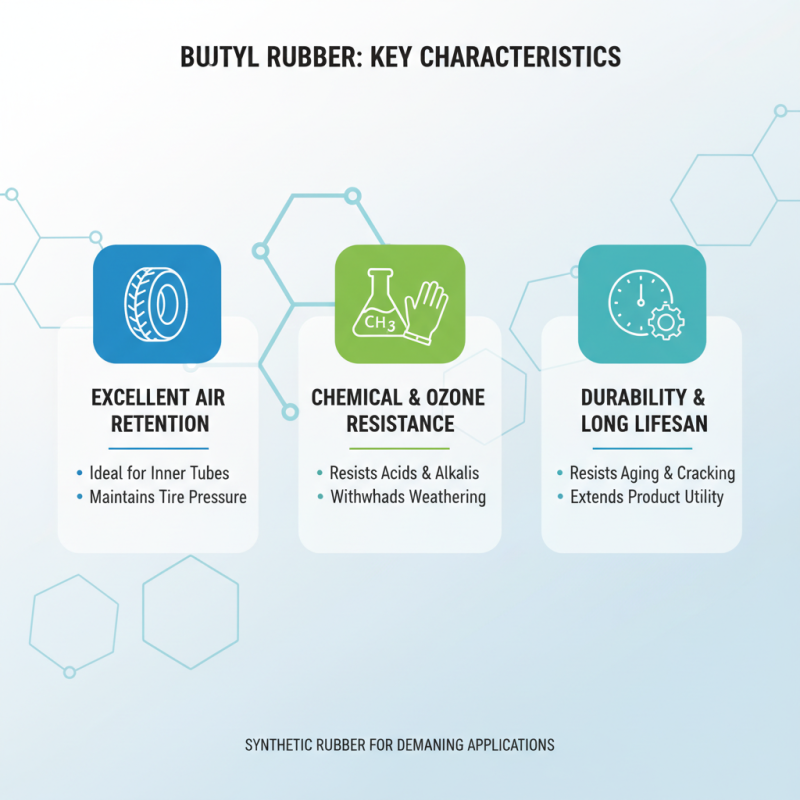

Butyl rubber is a synthetic rubber known for its unique characteristics. It stands out due to its excellent air retention properties. This makes it ideal for products like inner tubes for tires. It also has good resistance to chemicals and aging, which extends the lifespan of products made from it.

The structure of butyl rubber allows for a versatility that few other materials can match. It can be used in various applications, from adhesives to sealants. However, the production process can sometimes raise environmental concerns. Efforts to make it more sustainable are ongoing, which indicates a need for improvement.

Manufacturers often struggle with balancing quality and sustainability. The ideal butyl rubber is strong yet eco-friendly. Finding this balance is a challenge that requires ongoing research. The importance of butyl rubber is clear, but it needs continual refinement to meet modern demands.

Butyl rubber, known for its unique chemical structure, is significant in various applications. It is composed of isobutylene and a small portion of isoprene. This structure gives it valuable properties like low permeability to gases. Such features make butyl rubber ideal for tire inner linings, where air retention is crucial.

The properties of butyl rubber extend beyond just gas barrier capabilities. Its excellent resistance to aging and weathering keeps it durable over time. Additionally, its flexibility under various temperatures adds to its versatility. However, while it's often praised, it sometimes lacks superior tensile strength compared to other synthetic rubbers. This is a point of reflection for its use in demanding scenarios, where mechanical strength is paramount.

Butyl rubber is also a prominent choice in the pharmaceutical and food industries due to its non-toxic nature. Its compatibility with several materials enhances its usability in diverse sectors. However, this compatibility can sometimes lead to unexpected interactions, raising questions about its complete safety in sensitive applications. Overall, while butyl rubber has many advantages, users must remain vigilant about its limitations and the contexts in which it is used.

Butyl rubber is a synthetic rubber known for its excellent impermeability and aging stability. The chart below illustrates the global production and key applications of butyl rubber in 2023.

Butyl rubber plays a vital role in various industries. Its unique properties make it an essential material in manufacturing. According to the "Global Butyl Rubber Market Report," the market size was valued at over $3 billion in 2022. The annual growth rate is expected to be around 5% through 2030. This compound is noted for its excellent gas impermeability and superior aging stability.

In everyday products, butyl rubber is commonly found in tire inner linings. It prevents air leaks and maintains tire pressure effectively. In 2021 alone, the production of tires using butyl rubber accounted for nearly 60% of its total consumption. Furthermore, it's used in sealants, adhesives, and even in the medical field for certain rubber goods.

Despite its significance, not all industries are fully aware of its benefits. Some manufacturers may overlook the advantages of butyl rubber compared to other synthetic options. This lack of knowledge can hinder innovation. The industry's growth relies heavily on education and understanding of this material. Exploring butyl rubber could lead to more sustainable product development, improving both performance and environmental impact.

| Application Area | Description | Benefits |

|---|---|---|

| Tires | Used in inner tubes and tire linings for its air retention properties. | Enhanced air retention reduces tire pressure loss. |

| Pharmaceuticals | Used in bottle closures and seals for pharmaceutical products. | Barrier properties protect medicine from contaminants. |

| Construction | Used in membranes and coatings to waterproof buildings. | Provides excellent resistance to water and air infiltration. |

| Automotive | Used in gaskets, seals, and vibration dampening components. | Improves longevity and performance of automotive parts. |

| Sports Equipment | Used in inflatable products like balls and pools. | Durability and low permeability extend product life. |

Butyl rubber is a synthetic rubber known for its excellent airtightness. This characteristic makes it a preferred choice for many applications, especially in the tire industry. Its unique composition gives it resistance to gases. This quality sets it apart from natural rubber.

One major advantage of butyl rubber is its durability. It can withstand various weather conditions, which is essential for outdoor products. Additionally, butyl rubber has a lower permeability to gases. This makes it advantageous in applications that require sealing. Whether in sports equipment or medical devices, its reliability is crucial.

However, butyl rubber isn't without its challenges. It can be more expensive compared to some other types of rubber. This raises questions about cost versus benefits. This is something companies need to think about when choosing materials. But when performance and longevity are the priorities, butyl rubber stands out as a strong candidate.

Butyl rubber is a synthetic material that plays a crucial role in various industries. Its unique properties, such as low permeability to gases, make it valuable in tire production and sealants. However, its production and disposal raise environmental concerns. The manufacturing process often involves toxic chemicals. This can lead to air and water pollution.

The sustainability of butyl rubber is under scrutiny. Recycling methods exist, but they are not widely implemented. Most butyl products end up in landfills, where they can take decades to decompose. The industry must innovate to reduce waste. Efforts are underway to create bio-based alternatives. Still, these solutions have their own challenges, like cost and performance.

Public awareness is growing about the environmental impact of materials. Consumers are asking for greener options. Manufacturers may need to adapt to these demands. Ensuring sustainability while maintaining quality is not easy. The journey towards a more eco-friendly butyl rubber industry requires commitment and creativity.