Leave Your Message

Butyl Rubber, a synthetic rubber produced from the polymerization of isobutylene with a small amount of isoprene, has become a cornerstone material in various industrial applications and everyday products. According to a report by Market Research Future, the global demand for Butyl Rubber is expected to reach approximately 1.6 million tons by 2025, driven by its versatile properties and reliable performance. This remarkable material is renowned for its excellent impermeability to gases and outstanding resistance to heat, chemicals, and aging, making it ideal for use in tire manufacturing, adhesives, sealants, and medical products.

The unique characteristics of Butyl Rubber lend themselves well to numerous applications, both in industry and consumer markets. For instance, its ability to resist gases contributes significantly to the efficiency and longevity of tires, thereby enhancing vehicle safety and performance. In the medical sector, Butyl Rubber’s biocompatibility makes it a preferred choice for stoppers and seals in pharmaceutical packaging. As industries continue to innovate and seek materials that meet rigorous performance standards, the relevance of Butyl Rubber only grows. This article explores the top ten benefits of Butyl Rubber, illustrating its critical role in contemporary industry and daily life.

Butyl rubber, known for its unique properties, has become an essential material in various industrial applications and everyday use. Its low gas permeability is one of its standout characteristics, making it extremely effective for producing airtight seals and barriers. According to the "Rubber Manufacturers Association," butyl rubber can reduce air loss in tires by up to 90%, which significantly improves fuel efficiency and extends tire life. This property is particularly valuable in manufacturing leak-proof containers used in the storage and transport of chemicals, pharmaceuticals, and food products.

Another key feature of butyl rubber is its excellent resistance to aging and weathering. Research published in the "Journal of Applied Polymer Science" highlights that butyl rubber maintains its elasticity and physical properties even after prolonged exposure to harsh environmental conditions, making it suitable for outdoor applications. Additionally, its superior chemical resistance allows for its use in specialized applications such as medical devices and sealing products used in laboratories. This combination of durability and versatility underscores why butyl rubber continues to be a preferred material across various sectors, contributing to enhanced safety and performance in everyday products.

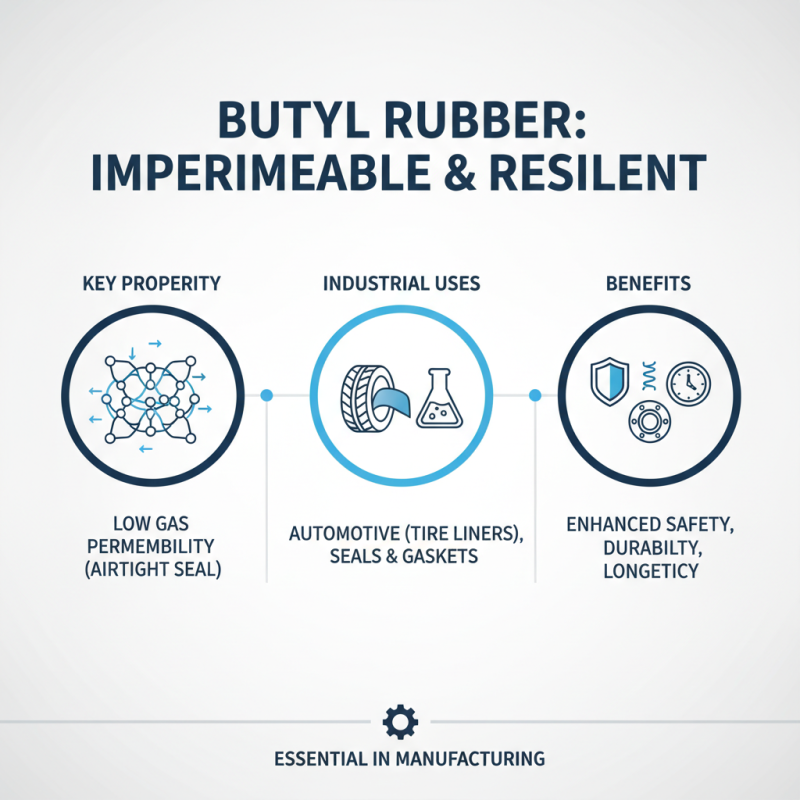

Butyl rubber, known for its exceptional impermeability and resilience, plays a crucial role in various industrial applications. Its primary characteristic, a low permeability to gases, makes it an ideal material for sealing products in numerous manufacturing sectors. For instance, in the automotive industry, butyl rubber is extensively used for tire inner linings, ensuring that air is retained effectively and enhancing the overall performance and safety of vehicles. This property is not just limited to automotive use; it is also beneficial in producing seals and gaskets that require high durability and resistance to environmental factors.

Additionally, the chemical resistance of butyl rubber allows it to be utilized in the production of linings for tanks and pipes that transport corrosive substances. Its flexibility and longevity are crucial for maintaining the integrity of these systems, preventing leaks and contamination. Industries involved in pharmaceuticals and food processing also leverage butyl rubber for its non-toxic properties, employing it in applications where hygiene and safety are paramount. Overall, butyl rubber's unique attributes make it an indispensable material across various industrial sectors, leading to improved efficiency and safety in manufacturing processes.

Butyl rubber, known for its exceptional impermeability and durability, has become a fundamental material in the automotive industry. Its low permeability to gases makes it ideal for tire manufacturing, where it helps maintain tire pressure over extended periods. This characteristic leads to improved fuel efficiency and enhanced safety, as properly inflated tires provide better traction and control. Butyl rubber's resistance to aging and weathering further ensures that automotive components, such as seals and gaskets, perform reliably in harsh conditions, reducing maintenance needs and extending the lifespan of vehicles.

In the aerospace sector, butyl rubber plays a critical role in enhancing performance and safety. Its lightweight nature contributes to overall weight reduction in aircraft, which is essential for fuel efficiency. Additionally, butyl rubber exhibits excellent resilience and can withstand extreme temperatures and pressures, making it suitable for applications ranging from fuel systems to cabin sealing. The ability of butyl rubber to resist swelling in the presence of oils and chemicals further adds to its appeal, ensuring that aerospace components remain effective and durable throughout their operational life, even in challenging environments.

Butyl rubber, a synthetic rubber known for its exceptional impermeability to gases, is widely utilized in various consumer products due to its unique properties. One of the most prevalent applications is in the automotive sector, where butyl rubber is used in inner tubes and tires. According to a report from the Rubber Manufacturers Association, butyl rubber's low permeability helps improve fuel efficiency by reducing air loss, making it a vital material for modern vehicles. This feature not only enhances performance but also extends the lifespan of tires, which leads to less frequent replacements and lower costs for consumers.

In everyday consumer products, butyl rubber is often found in adhesives, sealants, and coatings. Its weather resistance and durability make it an ideal choice for outdoor applications, such as roofing materials and window seals, protecting homes from moisture and air leaks. A study by the American Chemical Society highlighted that butyl rubber’s resilience against environmental factors contributes to energy savings in residential buildings, as it aids in maintaining indoor temperature. Additionally, butyl rubber is also used in items like athletic footwear, where its cushioning properties provide comfort and support during physical activities, therefore enhancing the overall user experience.

| Benefit | Description | Applications | Everyday Use |

|---|---|---|---|

| Excellent Gas Barrier | Butyl rubber is known for its ability to resist gas permeability, making it ideal for sealing applications. | Tires, containers | Inflatable products |

| Weather Resistance | It can withstand extreme temperatures and UV exposure without degrading. | Roofing membranes | Outdoor furniture covers |

| Chemical Resistance | Butyl rubber is resistant to many chemicals, allowing for use in various industrial environments. | Sealants, gaskets | Bathroom sealants |

| Low Permeability | This property makes it suitable for vacuum and airtight applications. | Vacuum seals | Food packaging |

| Durability | It exhibits high resilience and can retain its shape and characteristics over time. | Industrial belts | Sports equipment |

| Flexibility | Butyl rubber remains flexible under low temperatures, making it ideal for various products. | Electrical insulation | Flexible hoses |

| Vibration Dampening | It effectively reduces vibrations, making it useful in machinery and automotive applications. | Mounting pads | Anti-vibration mats |

| Non-Toxic | Butyl rubber is safe for various consumer applications, as it is generally non-toxic. | Medical devices | Children’s toys |

| Cost-Effective | Butyl rubber offers a good balance of performance and affordability in manufacturing. | Automotive parts | Home appliances |

| Recyclability | With increasing recycling programs, butyl rubber can be processed into new products. | Rubber products | Recycled rubber mats |

Butyl rubber, known for its excellent impermeability and flexibility, is increasingly recognized for its favorable environmental impact and sustainable qualities. The production of butyl rubber, when compared to traditional synthetic rubbers, typically involves a more efficient process that consumes fewer resources. This results in lower energy consumption and reduced greenhouse gas emissions, making it a more sustainable option for industrial applications.

Moreover, butyl rubber is highly durable and has a long lifespan, which contributes to its sustainability profile. Products made from butyl rubber can be reused and recycled, thereby minimizing waste. The material's resistance to aging and degradation means that items such as seals, tires, and hoses maintain their functionality over extended periods, reducing the need for frequent replacements. This longevity helps to decrease the environmental footprint associated with the manufacturing and disposal of rubber products, positioning butyl rubber as a key player in promoting sustainability in both industrial settings and everyday use.