Leave Your Message

Air chambers play a crucial role in various applications, providing essential functionalities through the control and management of air pressure. According to Dr. Linda Thompson, an expert in pneumatic systems, "The effectiveness of an air chamber in mitigating pressure fluctuations can significantly enhance the performance of hydraulic systems." This statement underscores the pivotal function that air chambers serve in ensuring stability and efficiency across different engineering sectors.

In essence, an air chamber is a sealed compartment filled with air that acts as a buffer, absorbing shock and accommodating pressure changes in systems such as plumbing, automotive, and industrial machinery. By understanding how air chambers function and their contributions to diverse applications, professionals can design more efficient and reliable systems.

Air chambers not only enhance operational performance but also improve safety and longevity of equipment. As industries continue to evolve, the importance of incorporating effective air chamber designs becomes increasingly apparent, making them a focal point for engineers and researchers alike.

An air chamber, commonly known as an air cushion, is a sealed space filled with air that serves various essential functions in different applications. Primarily, air chambers are used to absorb shock, reduce vibrations, and maintain pressure in hydraulic systems. According to the Hydraulic Institute, the use of air chambers in fluid systems can reduce pressure fluctuations by up to 50%, significantly enhancing the stability and longevity of equipment.

In plumbing and water supply systems, air chambers play a critical role in preventing water hammer—a hydraulic shock that occurs when fluid in motion is forced to stop or change direction suddenly. Research from the International Water Association indicates that appropriate use of air chambers can lead to a reduction in water hammer impacts by more than 30%, thereby prolonging the lifespan of piping and fixtures. Additionally, air chambers are utilized in hydraulic accumulators, where they store energy and provide a stable pressure environment in systems such as automotive hydraulics, lifts, and industrial machinery, leading to increased efficiency and reduced energy consumption.

Furthermore, air chambers are also significant in various industrial applications, such as in pneumatic tools and suspension systems in vehicles. The incorporation of air chamber technology optimizes performance and enhances comfort by effectively managing dynamic loads. According to data from the Society of Automotive Engineers, implementing air chambers in automotive suspension systems can improve ride quality by up to 25%, underscoring their vital role in modern engineering solutions.

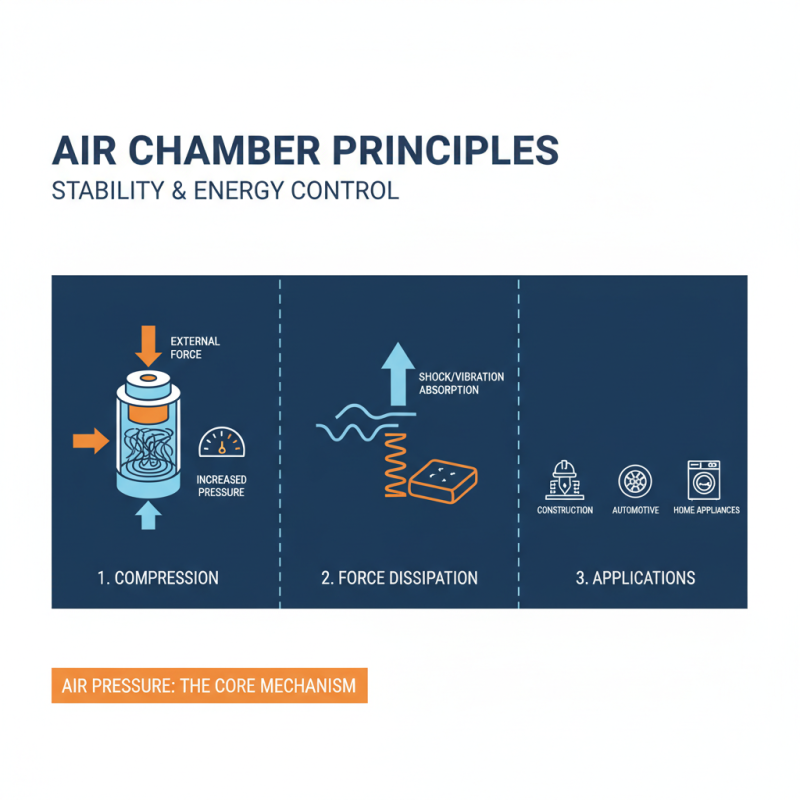

Air chambers are fascinating structures that utilize the principles of air pressure to function effectively across various applications. At the core of an air chamber is the concept of compressed air, which plays a critical role in maintaining stability and energy control. When air is contained within a chamber, it can be compressed, thereby increasing its pressure. This pressure creates a force that can absorb shocks and vibrations, making air chambers essential in applications such as construction, automotive engineering, and even in home appliances.

The physics behind air chambers can be understood through the relationship between pressure, volume, and temperature, as described by Boyle's Law. As the volume of the air chamber decreases, the pressure of the air within it increases proportionally, provided that the temperature remains constant. This characteristic allows air chambers to act as effective shock absorbers, where they can mitigate impacts by redistributing the forces exerted on them. In addition, air chambers can be used to maintain buoyancy in various marine applications, where the controlled pressure within the chamber ensures stability and safety in water. Thus, understanding the mechanics of air chambers offers insight into their versatility and importance in engineering and design across multiple fields.

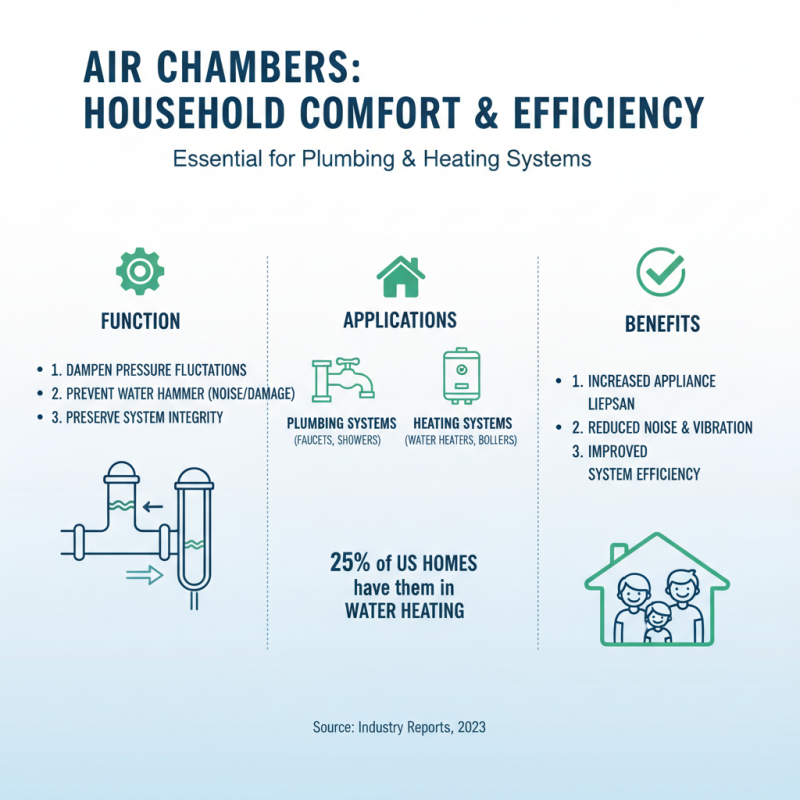

Air chambers play a vital role in various household systems, enhancing comfort and efficiency in our daily lives. Primarily used in plumbing and heating applications, these chambers serve as buffers that help to dampen pressure fluctuations, preventing water hammer and preserving the integrity of plumbing systems. According to industry reports, around 25% of domestic water heating systems are equipped with air chambers, indicating their widespread acceptance for improving performance and extending the life of appliances.

Another common application is in HVAC systems, where air chambers help to manage air flow and reduce noise levels. They act as expansion vessels that accommodate changes in pressure within heating and cooling systems, supporting optimal operation. Reports suggest that properly maintained air chambers can improve energy efficiency by up to 15%, benefiting both homeowners and the environment.

Tips: Ensure that your air chambers are regularly inspected and maintained to optimize their performance. Clear blockages that might impede functionality, and consider installing additional chambers in larger systems for enhanced stability. Furthermore, using a pressure gauge can help monitor system performance, ensuring that air chambers function effectively and prolong the lifespan of your household systems.

Air chambers play a crucial role in automotive suspension systems by providing a versatile and adaptable solution for shock absorption and ride comfort. Essentially, an air chamber is a flexible enclosure that can be inflated or deflated to adjust its volume and pressure, influencing the suspension's performance based on the vehicle's load and driving conditions. When the vehicle encounters bumps or uneven surfaces, the air chamber compresses, absorbing energy and minimizing the impact transmitted to the chassis. This ability to modulate stiffness in real-time ensures that passengers experience a smoother ride, regardless of the road conditions.

Moreover, air chambers enhance vehicle handling and stability during dynamic maneuvers. By varying the air pressure within the chambers, drivers can alter the vehicle's ride height and damping characteristics. This adjustability allows for improved traction and better control, particularly in sports or off-road applications. Additionally, air chambers can compensate for changes in weight distribution, such as when carrying loads or towing, ensuring that the vehicle remains balanced and responsive. Overall, air chambers significantly contribute to the performance and comfort of modern automotive suspension systems, making them an essential component in vehicle design and engineering.

Maintaining an air chamber is crucial for ensuring its effective performance across various applications. Regular inspection is the first step in maintenance—checking for any signs of wear or damage can prevent significant issues later on. It's important to look for leaks, which can diminish the air chamber's efficiency. Additionally, ensure that the pressure settings are appropriate for the system in which the air chamber is installed, as incorrect pressure levels can lead to operational problems. If the air chamber is part of a larger system, such as a pressure tank or a plumbing system, checking connected components for proper function is also advisable.

Troubleshooting common problems is essential for keeping an air chamber in peak condition. If you notice irregularities such as unexpected sounds or fluctuating pressure, it may indicate underlying issues. Start by examining the valves and fittings for blockages or damage. For chambers equipped with a diaphragm, check for any tears or punctures, as these can lead to inefficiency. In instances where the chamber fails to maintain pressure, inspecting the air supply and replenishing it as necessary is vital. Keeping a detailed maintenance log can help track any recurrent issues and ensure timely interventions, ultimately extending the lifespan of the air chamber.